Hunt Wheels are “Honoured to create wheels for devoted bike riders”.

“You ride every chance you get”, “You push on through wind and rain” and “Your time and money must deliver results”.

In the line above, the first two statements made by Hunt’s Marketing Department may not apply to every gravel cyclist, but the last certainly does. Wheelsets should deliver value for money and performance.

Hunt Wheels are based in the UK, and gaining traction as a company renown for manufacturing value for money wheelsets in aluminium and carbon, with free shipping worldwide. Everyone loves free shipping! Like so many manufacturers these days, Hunt Wheels are built in Taiwan, but they go a little farther than your average wheel company. Hunt Wheels utilize the services of Mr. Hao-Cheng, Hunt’s wheel building partner.

Mr. Hao-Cheng has built and finely tensioned tens of thousands of wheels for leading high-end brands during his many years as a master wheel builder. Additionally, Hunt passes their wheels through a two-person build and finishing process. This ensures each wheelset has a complete quality control inspection, where all features of the build are checked.

Finally, the wheelset is signed off personally by the builder on the individual control card and included with your wheelset.

Hunt 30Carbon Disc Specifications and Weight

Plopped onto the trusty Gravel Cyclist gram scale, the front wheel with rim tape installed weighed 672 grams.

And the rear wheel, 794 grams with rim tape installed. The combined weight is 1,466 grams, 13 grams less than the manufacturer’s spec weight of 1,479 grams. Taking into account most manufacturers weigh their wheels sans rim tape, it’s refreshing to see Hunt Wheels are spot on / below with their numbers versus marketing claptrap. The sample wheelset is likely sub 1,460 grams sans rim tape, which is impressive considering the stout nature of its build.

The rims in Hunt’s 30Carbon wheelset (30 referring to the rim’s depth) are manufactured from unidirectional T24/30 carbon fiber, and a 3K carbon weave is used to reinforce the spoke holes. This rim measures 26.6mm outside to outside and 21.3mm internally.

The rim features a rounded, aero profile that is designed for good handling qualities in all angles / wind directions, and excellent straight-line speed. Because these rims are disc-specific and not reconstituted from a rim brake design, Hunt has removed material from appropriate spots in the rim to drop the weight, while maintaining strength to support the forces generated by spokes and tyres.

“V:Absorbe” resin, part of the rim construction process, is a low-temperature resin and hence less brittle, making for a rim that has better resistance to impacts. Hunt claims this resin helps with vibration dampening.

“H-Lock” is Hunt’s tubeless-ready rim bed profile, which promises to lock the tyre beads more securely in place once the tyre has been properly seated. Hunt claims their “H-Lock” design makes for easy tyre installation.

Maximum tyre pressure is dependent on tyre width:

- 25 to 28mm, 110psi max.

- 30mm, 80psi max.

- 33mm, 60psi max.

- 35mm to 45mm, 40psi max.

- 46mm+, 35psi max.

Heed these recommendations. Excessive air pressure can damage the rim resulting in a potential rim failure.

Hunt doesn’t skimp on spokes, selecting Pillar’s XTRA stainless steel bladed and butted aero spokes and 14 gauge, external aluminium nipples in anodized black.

Twenty-eight spokes front and rear laced in a two-cross pattern provide plenty of strength.

At the heart of Hunt’s 30Carbon Gravel Disc Wheelset is the company’s “4Season” Disc brake hubs. The “4Season” hubs feature additional bearing shielding and seals for endurance in all weather conditions.

Above, the Hunt cassette body features a steel insert aka “Anti Bite Guard”, to prevent cassettes from scoring the body’s soft aluminium.

High-quality Japanese EZO bearings are present in the front and rear hub.

Both hubs are well thought out and potentially future proof, catering to almost every axle standard relevant to disc brakes. For the front hub, a set of easy to swap end caps provides compatibility with a standard quick release, 12mm, and 15mm thru-axle. The rear hub caters to standard quick releases and 12mm x 142mm thru axle once a simple axle swap has been made. Hunt’s instructional videos and FAQ’s are very easy to follow.

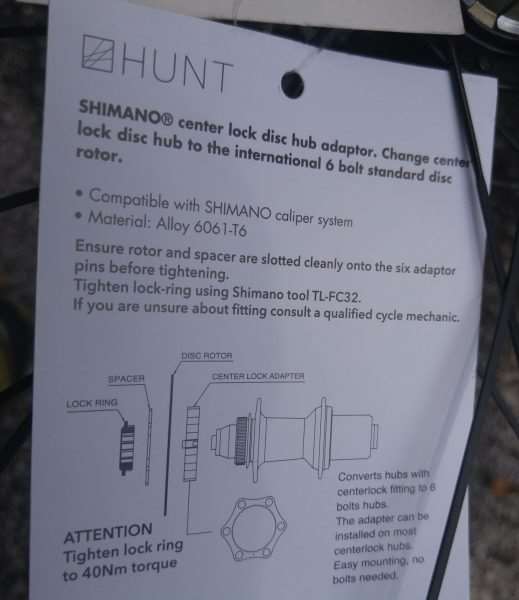

Hunt has wisely chosen Shimano’s centre-lock standard for the mounting of disc brake rotors. But, bikes with 6-bolt rotors are not left out in the cold. A pair of 6-bolt adapters is included with each wheelset.

Finally, pictured above is the comprehensive set of axles, end caps, rotor adapters, quick releases, truing key, tubeless valves and spare spokes, supplied with every Hunt Wheelset for maximum compatibility. To my knowledge, Hunt Wheels are the only company who provides such an extensive support package. Priced out individually, you’re looking at somewhere around $US 100 worth of accessories, gratis.

Hunt 30Carbon Gravel Disc Wheelset – Disc Rotor and Tyre Installation

In today’s world of gravel cycling, virtually every new bike is equipped with disc brakes. That entails a minor dilemma in itself with two different standards for mounting disc brake rotors. As for the mechanisms that attach those wheels to one’s bike, quick releases or thru-axles, these standards make it difficult for a manufacturer to supply a wheelset that is ready to roll for the consumer, direct from the factory. As alluded to earlier, Hunt’s versatile hub design covers all of the standards, but they take the extra step of noting at order time, your axle preference. The Hunt Wheels arrive at your doorstep with your preference of axle, ready to roll.

The Hunt review wheels mostly found their home on the Orbea Terra gravel review bike, a machine I reviewed earlier in 2017. That bike utilized 12mm thru-axles front and rear. Because Hunt shipped the wheels ready to go, there was no need to swap end caps or axles.

Pictured above, you can see what a doddle it is to swap a front wheel end cap to cater to a different thru-bolt size. No tools, less than one minute, done!

Rotor installation is a snap with center lock, and the fastest of the two rotor standards. The time I can save with review wheels, swapping rotors back and forth, is really appreciated!

For the duration of the review, I mounted and ran two different tubeless tyres with the review wheels. The Schwalbe G-One tyre in 700c x 40mm and WTB’s Resolute tyre in 700c x 42mm. Both tyres mounted easily to the wheels, without the need to pry them on with tyre levers. The tyres inflated nicely, courtesy of Bontrager’s TLR Flash Charger pump, but I’d expect the Topeak Joe Blow Booster pump would have no troubles either. Using an air compressor? Even easier. Sealant used was Orange Seal’s fantastic Endurance Formula.

Hunt 30Carbon Gravel Disc Wheelset – The Ride

At sub 1,500 grams, the Hunt 30Carbon Disc wheelset is among the lighter pre-built offerings currently on the market. Their low weight translates into fast acceleration and excellent handling characteristics, particularly in crosswinds. Once up to a nice rolling speed of 20mph / 32km/hr on a fast, smoothish gravel road, the Hunt 30Carbons tick along nicely and maintain their speed well. The aero effect of these wheels is questionable, especially when you factor in how disruptive a 42mm wide gravel-specific tyre can to be to air flowing across the bike. But the placebo factor is well-proven as a positive. If you feel fast, you are fast. The Hunt 30Carbon Disc wheels felt fast, and I wouldn’t hesitate for a moment to do double duty with these wheels on a disc brake road bike.

The Hunt 30Carbon’s 28 Pillar, aero butted J-Bend stainless steel spokes provide a measure of aero benefit, but replacement spokes beyond the two spares supplied will be tricky to find in a local bike shop. In Hunt’s defense. any decent bladed spoke could substitute as a replacement, along with a garden variety double butted or rounded spoke. For the duration of the review, the Hunt 30Carbon wheels stayed perfectly in true, a good testimony to the skills of the wheel builder.

Hunt Wheels aren’t flashy or covered in garish logos, rather, their focus is on price, performance and simple good looks. Riders who appreciate the subtler side of aesthetics will appreciate the subdued look of the Hunt 30Carbon Gravel wheelset.

In sticky situations like the one pictured above, the rear hub’s 4-pawl, 28-point engagement system was appreciated. This is one of those times when you need to finesse your line carefully, which sometimes calls for a last-second change in direction. At worst, 12.85 degrees of movement has to occur in the Hunt’s rear hub before the forward driving mechanism is engaged. Coasting along, freewheel operation is very quiet.

The Hunt 30Carbon’s have a rider weight limit of 115 kilograms / 253 pounds. Yours truly weighs anywhere from 153lbs to 160lbs/69kg to 71kg, depending on how much I’ve been riding or stuffing my face. The wheels have been absolutely rock solid. I’ve been unable to budge them laterally during out of the saddle efforts, but this isn’t to say their stiffness makes for a rough ride.

Tyre pressure is one of the biggest factors to ride quality and the most overlooked factors regarding overall comfort on a bicycle. It’s no wonder I spot riders squawking about the merits of suspension on gravel, yet their tyres are inflated to 50psi or higher. Crazy! Drop your tyre pressure and save yourself hassle and expense! Depending on the tyre, I generally inflate to 32 to 35psi on the front, and 35 to 38psi on the rear. That said, once your tyre pressure has been set appropriately, the Hunt wheels are indeed a smooth ride.

There is one sticking point with the Hunt 30Carbon’s I must mention. The sample tyres used with this wheelset, the WTB Resolute and Schwalbe G-One were extremely difficult to remove from the rims. I did a serious number on my hands, trying to wrench these tyres free. To say these tyres were securely mounted to the rims is an understatement. On one occasion, I was able to pry tyres free, but on every other occasion, I had to enlist the help of a local bike shop mechanic… whose hands are stronger than mine… and I swap tyres between wheels regularly.

I don’t believe the sample tyres were overly tight on the rims, as they installed so easily. Perhaps the sample wheelset is a pre-release before the production model appeared (this happens sometimes)? Regardless, this is a legitimate concern. Should you flat a tyre on these wheels, breaking the bead from one side will be a challenge, and may have you calling home or Uber. Considering how well these wheels ride, this is a shame.

Hunt 30Carbon Gravel Disc Wheelset – Braking

What’s not to love about Shimano’s hydraulic disc brakes. Mount your disc brake rotors, align them with the calipers and go ride. Zero issues. Hunt 30Carbon Gravel Disc wheelset or otherwise, if your bike is fitted with hydraulic brakes of any kind, there’s a good chance they’ll bring you to a screeching halt in wet and dry conditions.

Hunt 30Carbon Gravel Disc Wheelset – Summary

The Hunt 30Carbon Gravel Disc wheelset is exceptionally well-built and proven to be a reliable and flexible package that is perfect for gravel cycling – or road cycling – on a suitably equipped road bike. The wheelset is designed for tubeless use but is perfectly capable of running with tubes. I applaud the use of J-bend spokes, even if they are aero in nature. Replacement J-bend spokes can be found at any good local bike shop.

The front wheel end cap system and easy axle swaps for the rear wheel make this wheelset almost future proof… until the next standard is invented. But, the difficulty I experienced when removing tyres is a problem. Perhaps it was just my sample wheelset, but it is something to be wary of. This issue aside, the Hunt 30Carbon Gravel Disc wheelset is light, fast and arrives at your front door with an impressive array of accessories.

Pricing

The Hunt 30Carbon Gravel Disc wheelset is well priced at $US 1,344.00 / £969.00 GBP (remember, the exchange rate varies), which includes free shipping worldwide! Compare this to a wheelset of similar weight and you’ll be paying a lot more. This price includes pre-installed rim tape, valves, end caps, skewers, 6-bolt rotor adapters and spare spokes.

When you say that these are difficult to remove tires from, do you mean difficult to remove with tire levers, or difficult to remove just by hand?

Difficult to remove by hand… tyre levers don’t budge it either.

I have this issue with Hed Ardennes wheels. Better get your miles out of the tire and not have a flat ‘cuz you’re not gonna get it off the rim without extremely strong hands or by destroying the tire.

Couldnt wait to see the price. Price seems fair but towards the end you mention difficult tire removal…that is a no go for me.

Yes, I don’t know if it was just my sample pair, or a problem with every one of their carbon wheels? I did bring it to the attention of the company before I posted the review.

Afraid I can’t find the review(s) but I have seen at least one other that mentions difficult tire removal. I think they thought it might have been down to a combination of tire tubeless standard being used and the internal rim profiling i.e. unlikely a one-off.

Personally, I’ve got a set waiting in the garage to try on the new bike. Decided they look like great wheels and I’ve had previous “fun” with tubeless tires rolling off rims before so this seems like a reasonable tradeoff. Fairly confident if all else fails carefully standing on the tire with your heels and using body weight to break the bead will work as well … at least for me anyway :-/

“Fairly confident if all else fails carefully standing on the tire with your heels and using body weight to break the bead will work as well … at least for me anyway :-/”

This bit hits home a bit. We would have similar issues breaking the bead on adventure style motorcycle tires (i.e. Honda Africa Twin). We would do just as you said, stand on the rim/tire to break the bead or use the kickstand with the weight of the bike. That said, everything changes when we are talking carbon bicycle rims. I don’t know if I’d trust myself to stand on them!

I love the simple black rims. Matt black doesn’t show dirt. Easy to towel off.

I wonder what the track record is on failure when confronted with a

river of baby heads?

I’ve never seen you towel off a bike bwahahahaha!!!

please let us know how the company addresses the ‘impossible removal’ problem. Wheels look good, but broken bleeding knuckles are a sure deal breaker.

cheers

Stephen

Definitely not impossible, but if you don’t have strong hands, you’re going to be in trouble.

I’d like to know how Hunt responds as well. Otherwise I can see buying to sets of these with out a second thought.

I bought and rode their Carbon Aero 50 disc wheel set at DK200 last year and they performed flawlessly. In fact I’m still riding them in absurd conditions and they’re fantastic. I’ve done a complete hub cleaning a couple of times and the bearings are still rolling smooth. No exaggeration, they’re the greatest bang for your buck you can buy.

Hi Stefano. No problems with removing tyres on the 50mm rims?

I can’t say I’ve had a problem yet. In fact I had to get the rear tire off with one lever to put a tube in after a large gash took out my Compass Snoqualmie Pass this past weekend. May be a different bead shape on the 30s?

@Stefano. Have you tried non-Compass tires? I’ve found my Compass Barlow Pass are easy to install (without any tools) on rims that are otherwise quite difficult with (e.g.) Schwalbe tires — even with tools.

Good to hear. I’d like a set of those for my road bike.

JOM…Maybe the issue is your wee hands lacking in strength?

That’s a definite haha. The mechanic, who I will not name, did have difficulty prying the tyres off. It shouldn’t be this difficult considering I can swap tyres on other wheels sans worry!

I guess the question is “given how difficult they were to install/remove tires, would you buy these rims if you expected to eventually flat out on the road without anyone to assist you?”.

I agree with other commenters that this is a significant consideration. I probably would not buy wheels that I wasn’t confident I could throw a tube in if I split the tire open on a ride. Especially carbon rims. (I have had difficult rims and bought metal levers and the Crank Bros Speedier Levers, but not sure I’d be as confident going to town with aggressive tools on the carbon sidewalls?)

Yes Andy…JOM once told me if we ever get in a fight we’d both lose! Of course most serious cyclists are pretty avian-like to begin with. Also JOM, is a “Hope V-Twin mechanical to hydro converter brake set” even a real thing? I think you made that up…sort of like Steve Martin’s “7 angstrom ganglia wrench” as a plumber’s joke.

I’m just sayin’ 🙂

Would I lie?! I’ve seen some of the fancy bollocks you keep at your fireplace store… with associated weird names 🙂

Great and very through review. As always!

So, I definitely agree that $1300-1400 compares well against name-brand wheelsets. But in this specific case, these are Novatec hubs laced to Taiwanese (open mold?) rims, so it seems more apples-to-apples to compare them to the BDOP DTO-40 wheelset, which uses the same hubs (including the Japanese EZO bearings — I assume Hunt gets theirs from BDOP). https://bdopcycling.com/DIY%20Carbon%20Road%20Disc%20Kit%20III.asp

Granted, that rim on the BDOP is a very light rim, probably not ideally suited to rocks, etc. And they’re narrower than ideal for bigger tires too. But I think it might be a better price comparison.

I think Hunt would do well to spec Hope Pro 4 hubs (also a UK product) on these instead of Novatec. Novatec hubs are ok (I have two sets of Novatec wheels for commuting), but they don’t have the durability or strength/rigidity (or engagement-point count) of something like a Hope hub.

Relatedly, there are a couple very interesting options available from mainland China outfits:

(1) The LB 36mm hookless rim (https://www.lightbicycle.com/Road-bicycle-rims-28mm-wide-36mm-deep-aero-clincher-road-disc-brake-available.html) or

(2) The new Yishun 33mm asymmetric rims (https://www.yishunbike.com/road_rims-132-2017-road-disc-brake-asymmetric-rims-road-disc-brake-rims)

I’ll be building up a set of the LB rims. (I have the 46mm-deep variants on my road bike laced to Hope RS4 hubs.) And I’ll probably pick up a set of the Yishun rims to cross-compare. The 46mm LB rims were trivial to mount & seat Schwalbe Pro One tubeless tires.

Hope components, absolute jewels. I once owned a Hope V-Twin mechanical to hydro converter brake setup. A clunky solution but Hope goodies are so well made.

Unfortunately, I don’t have available time to research all of the options, but Hans, I really appreciate you chiming in with a very informative post. Thank you.

Good luck with your wheel build projects.

Hi Hans,

Thanks for your detailed response and comparison, and you’re definitely right in highlighting that it is difficult to compare open and closed mold products. What we would always highlight is that just because a product comes from a closed mold, does not make it inherently better. In fact, the bigger companies using closed mold products is actually for their (commercial protection) benefit more than actually benefitting the rider. But yes this is definitely one of the many factors that puts our competitors’ price points so far north of our own.

You do make a good (and correct) point about the availability of parts in the far east – it certainly is much easier nowadays for riders to build and spec their own wheels. That said, we don’t source ‘build kits’ like that one from BDOP. Similar to the above, it’s difficult to compare like for like as with the above you’re ordering components individually whereas with our wheels you’re getting a complete package which is worth more than the sum of its parts. If you would like me to head into any more detail here, please let me know.

We’re proud to work with selected suppliers in the far east really pushing the boundaries of manufacturing standards. We work with a supplier widely considered to be one of the very best in Taiwan, and actually spend around 50% more on our rims than we would if we bought an off-the-peg equivalent from mainland China. There is a huge difference… and this extra investment is definitely worth it. When visiting said rim supplier in Taiwan not long ago, our senior wheel engineer Luisa (formerly of Campagnolo/Fulcrum and 3T) was amazed at just how perfectly smooth and well-finished the rims were once the molds were opened, which is indicative of an incredibly low void rate. Low void rates in carbon rims point directly to strong results in terms of structural integrity.

You also have correctly identified those hubs as Novatec, although would argue that the durability/longevity of them is incredibly high. With the double-sealed bearings, we have thousands of riders who have covered some quite remarkable distances in all sorts of conditions across different disciplines, and the hubs have absolutely shone through in terms of their capabilities.

We’re able to offer such competitive prices not through a low standard of component selection, but from a lean business model selling directly to you, the rider.

I hope all of the above makes some sense and would always welcome feedback or discussion on any of the points raised. Please feel free to get in touch directly if you wish to discuss component choice or any more aspects of Hunt Bike Wheels as I’d be happy to go into more detail and clarify on any questions you may have.

Warm regards,

Ollie Gray

Hunt Bike Wheels (Brand Manager)

Ollie, thanks so much for chiming in. I’ve been corresponding with your marketing person this entire time (Hamish), but it is very refreshing to hear from someone inside the company. This doesn’t happen too often. I’m sure the G.C. site audience appreciates you writing in as well.

Jayson (aka JOM)

Hi Ollie –

Thanks for following up with an even more thorough response! I hope that my comment didn’t come off as implying that these were poor-quality wheels — or evan that they’re over-priced! My point was to suggest that it’s worth mentioning a caveat in comparing these to a set of (e.g.) Zipp wheels that would be twice the price (or more).

But, yes, I agree completely that an open-mold product does not make it a worse product. Only that this might be a consideration when considering the cost (or at least the wholesale cost of parts). That said, it’s probably not worth really factoring in, because unless you’re looking for some specific aerodynamic R&D (which I’d argue is irrelevant here for gravel rims), there’s no value [to me, anyway] in a proprietary rim design.

And, good point on the wheel being more than the sum of its parts. For us in the US warranty value is probably a little hazier as it would cost a bit to ship them back across the Atlantic, but for local consumers that certainly would be a huge factor. I know one anecdote of someone cracking a DTO40 rim (riding into a wall) and while BDOP was great about replacing it for basically the price of shipping, there is certainly value in knowing that a wheel is well-built and that there’s a company that stands behind it. (Because I’m always building my own wheels I tend to overlook this.)

Finally, I think it’s probably worth mentioning that I’ve had only a bad experience ordering Chinese mainland *wheels* (not rims). I ordered a complete set of wheels once thinking that it was worth the gamble and I could just fix the build if there was a problem. Well, I had to completely rebuild both wheels and the spokes were too long on one of the wheels, so it didn’t save me any time or money in the end. So I definitely do not think it would be appropriate to price-compare Hunt wheels with something pre-built from Farsports, etc.

I do think Light-Bicycle rims would be worth evaluating, if you have not already. My experience is that these are very well finished rims. I have not cut them open, but it is always reassuring when weight is exactly as stated (within a couple grams) and ERD is also exactly as published. They have a strong reputation in the MTB world. Of course, they are also not the cheapest option — or the lightest. They build up true with even tensions, though, and have been a joy with tubeless. This is only based on a couple of data points, admittedly (soon 3). But I have built a few other far-east wheelsets.

And I probably should be less harsh on the Novatec hubs. These are much better, in my experience, than Bitex hubs. But I would not put them in the same league as Hope. I had Hope hubs with 25k all-weather miles without ever even looking at the bearings. On both of my D772SB Novatec hubs (one alloy axle, one steel axle — both from BDOP with EZO bearings) I get occasional pawl-engagement noises (a bit of a “skip”) just riding along. Not a real problem, but not inspiring and not something I would ever expect to happen with a Hope hub. And the 15mm front endcaps squeak occasionally (grease fixes this, but it’s fussy and again, just not something that would feel great on a top-shelf wheelset). Of course Hope Pro 4 hubs are also a bit heavier. But I would pay (or recommend others to pay) extra for those hubs.

Just this morning, though, I was riding with a friend who said she just ordered a set of Hunt 30. To which I replied that these look like awesome wheels. — The weight is very impressive for rims of those dimensions.

JOM – thanks again for another “real world” review. You take a very refreshing user perspective on everything you test. I agree with other commenters that tire removal issues, unless Hunt does something about it in future production runs, is a show stopper for me. This is an area that the the industry hasn’t adequately addressed. Over the years, I’ve purchased several carbon clincher wheel sets that made tire removal a nightmare. I’ve also tried various tools that are supposed to solve this problem; they help but not enough.

Hi JOM,

Thanks for the glowing review and really glad to see you enjoyed your time on the wheels. With regards to the difficulty in removing the tubeless tyres, we’re sorry to see this was the case and hopefully can clear up on a couple of bits that may contribute to this difficulty generally speaking, as well as go into some more detail on our wheels. Obviously, with the advent of tubeless, there are a few key factors which I’m sure you’re already well aware of from having tested so many of them. I’m sure most of your readers are also aware of some of these factors (particularly in this sector). The need for a tight seal between the rim-bed shoulders and the tyre bead is of much greater significance than with conventional tubed systems. With this in mind, added to the fact that sealant can (and will) assist with ‘locking’ the bead into that crevasse, we can see how – when paired with a couple of variables I’m about to discuss, this situation can occur quite easily.

The primary variable here is, of course, the tyre. We’d say we’re probably world-leaders in the fitting of tubeless tyres, as we fit around 7000 in our workshop over the past year alone!! This has taught us a lot about the variability between models (primarily, their bead construction). For example, tyres using a bead formed from an aramid compound (e.g. Hutchinson Fusion) are far easier to get on & off, although sometimes do not form as tight a seal as would be preferred – it is more often tyres with aramid compound beads that slowly let air escape over time. This can also be alleviated by running your finger with some addition sealant around the rim-bed shoulders prior to ‘popping on’ the beads with airflow.

Conversely, tyres using carbon-compound beads such as Schwalbes, are much firmer. On the plus side, they make a resounding ‘click’ when they jump up onto the rim-bed shoulders and once they’re on, you absolutely know they’re secure & safe, and air will not escape. However, conventionally, these may be the tyres slightly more difficult to remove at the roadside. There is also a lot of variability between tyres of single models themselves. When we were in Germany performing some wind tunnel testing a couple of weeks ago, using Schwalbe Pro One 28c tyres we found some could be popped onto rims by hand, and some were much (much tighter) – so this is always something to consider.

Saying that, we would not expect anything to be quite so difficult as what you’ve faced with yours, and we’d say unfortunately your issue has represented the exception much more than the norm. Owing to both our voluminous fitting of tyres on-site, as well as our close feedback loop with our customers – our systems absolutely have to work, and we hear about them very quickly if they do not. This is a most unusual case, given the lengths you’ve gone to to get the tyre off! We’re super appreciative of this feedback as it helps us directly in terms of our development. Obviously we’ll follow this up and speak with Hamish about the serial number of that wheelset, as it’ll help us look at the batch from which they came and definitely check our records for QC checks etc. The ease and usability of tubeless tyre systems is something I am always discussing ongoing with Tom & Pete (Directors) and Luisa (Senior Wheel Engineer), so this feedback is invaluable to those discussions.

I hope all of the above makes sense, and would welcome any enquiries to [email protected] – the team here will be more than happy to clarify any queries you or any of your readers may have. User experience is only going to continue to help us make better wheels, so I thank you and your readers again for your feedback that facilitates this development.

Warm regards,

Ollie Gray (Hunt Brand Manager – Road & CX)

Ollie, thanks for the detailed reply. I HUGHLY appreciate a manufacturer’s willingness to reply directly to the consumer. I’ve been looking for an relatively inexpensive set a carbon wheels for both my road bike and my CX bike. These wheels as well as the Aero 50’s you produced have certainly caught my eye. The support and customer service looks to be something I can get behind as well.

Ollie – thanks for your detailed reply. I was an early adopter of road tubeless tech. Over the years. The results have been mixed for me. And even before tubeless, I’ve had some serious issues with clincher tire fit. The problem from a customer user perspective, is that as you point out, there is a great deal variability between tires -even within the same make and model; perhaps less so in rims. This problem is something the industry needs to fix with improved standards and quality control. Frankly, I’ve encountered this problem too many times myself, and judging by the negative replies here, from other GC readers, my complaints, I’m not alone. To me at least, your implication that this is a “fluke” rings on deaf ears. I’ve just heard that explanation too often to give it much credibility. Remember, when your company is mounting and removing tires, you are usually working in a clean dry well lit environment. Your technicians have the best tools and massive experience and how to deal with stubborn tires. We customers, have to deal with much less ideal conditions, with much less experience. It just should never be this hard.