May 14, 2020, saw the unveiling of Corima’s first foray into the burgeoning market of products for gravel bikes, with the launch of their G30.5 wheelset. Founded in 1973, Corima’s initial activities included the manufacture of molds and models, for industries such as aeronautic and automotive. In 1988 Corima had diversified into the manufacture of composites, which resulted in the production of their first bicycle-related product, a carbon fibre disc wheel.

Since then, Corima has gone from strength to strength, and nowadays is one of the premier wheel manufacturers, having perfected the craft of carbon fibre wheel construction over the space of some 32 years. Best known for their venerable four-spoke wheel designed for time trialling on the road or velodrome, the company has produced innovative full-composite wheelsets such as their three-spoke and MCC DX wheelset, and more recently, wheels that use regular steel spokes, albeit in reduced spoke counts.

Corima’s latest G30.5 wheels are designed exclusively for use on gravel roads, with the added convenience of tubless rim technology. The G30.5 wheels use a hookless, TSS (Tubeless Straight Side) rim profile with an internal width of 22mm. The TSS profile has been reinforced with additional material to resist damage from impacts.

Video Review

**1,000 humble apologies for the small amount of out of focus footage in the first scene**.

More Corima G30.5 Tech

To ensure proper seating between the rim and tubeless-ready tires, the rims have been designed to strictly adhere to ETRTO standards. This allows for easy tire setting and inflation with no risk of the tire coming off. All Corima wheels are filled with structural foam and a horizontal UD carbon fiber bar to increase overall rigidity and strength.

The Torsion Box concept created and patented by Corima in the 1990’s, significantly reduces the flex found in ALL hollow carbon rims. This stiffness allows for enhanced power transfer in the most direct way possible to the ground, to push the bike forward. Because of this internal structure, the wheel is able to keep its trueness better under load. This core also helps to absorb both vibrations and sound for a quiet and more comfortable ride.

Internal Pressure Protection

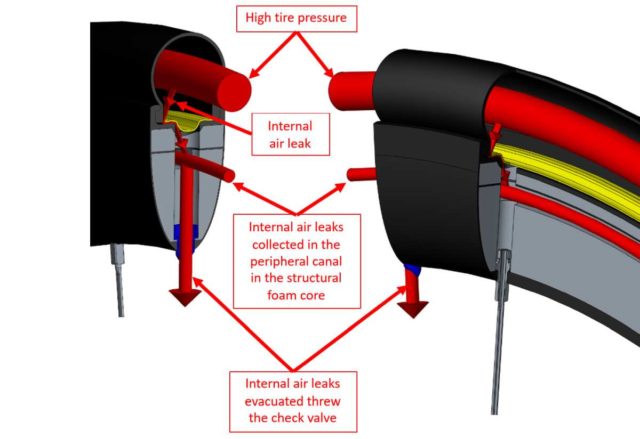

Mentioned earlier, Corima’s rim design features the patented use of an internal aerospace foam core. This foam core offers additional road vibration damping as well as an increase in rim strength and rigidity. This design created an additional challenge for the TLR setups and required a revision to the internal foam to eliminate the possibility of rim failure due to over pressurizing the internal rim space.

During the initial tubeless tire setup, there is the possibility for air to leak around the valve core or edges of the tape and into the rim. In these instances, the foam core would not allow air to evacuate from the internal cavity through the spoke holes. As a result, the internal cavity would become pressurized leading to possible rim damage. To solve this, a small channel was cut into the foam around the entire circumference of the rim. This channel leads to a vertical opening with a check valve on the exterior of the rim. If air leaks into the cavity on initial setup it travels through the rim channel, to the vertical opening and is automatically released through the check valve protecting the rim from damage. The check valve also helps prevent water from getting into the rims with a one-way flow while allowing air to escape.

This resulting design change allows the TLR rims to continue to take advantage of the increased strength and rigidity of the internal foam, as well as the additional road damping while ensuring that rims are not damaged during tire setup.

At the heart of the Corima G30.5 wheelset are DT Swiss 240S hubs for the centerlock interface. These hubs are renowned for their durability, reliability and easy availability of spare parts. They are configured for 12mm thru-axles front and rear for the Shimano 11-speed cassette interface, but the front hub can be switched to 15mm thru-axle with some different end caps. The rear wheel’s cassette body can be substituted for a Campagnolo or SRAM XDR unit.

Made in France

Corima is recognized globally for its expertise and innovation in carbon composite design and renowned high-performance wheels. Corima hand-builds their wheels in Loriol sur Drôme, France.

Each wheel is individually molded using prepreg carbon fibers, which are also handmade. Their in-house production process encompasses all steps in the development and manufacturing process from design, to final assembly.

Weighing approximately 1,535 grams (715 grams front, 820 grams rear), the Corima G30.5 wheels are priced at $US 2,200. Additional details are available at Corima / Corima USA.

Links of Interest:

Don’t forget to Like the Gravel Cyclist Facebook page, follow G.C. on Instagram and subscribe to our Youtube Channel. We are also on Twitter!

Please publish the rim weights. Manufacturers use wheel weights to avoid telling you what hte rims weigh.

You ask the same question every wheel review. How about you ask the manufacturer this question? I am not going to pull apart a wheelset on your behalf to ascertain the weight.

It’s because it’s a valid question. Manufacturers should list the rim weight as well (most good ones do)

Understand! I wish I could help you guys out, but I am not disassembling a wheel to answer the question.

240s front hub =107 gm.

Rear hub = 258 gm.

Aero light spoke 4.43 gm.

Nipple .34 gm